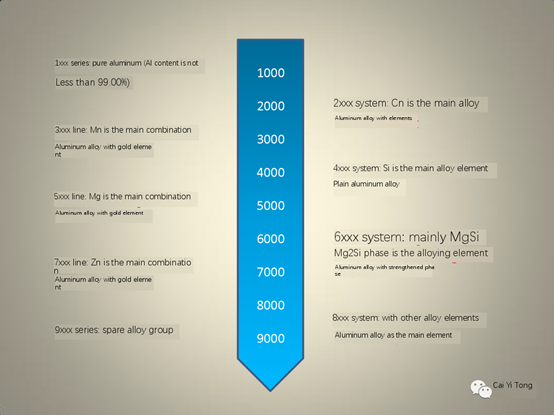

Classification of aluminum alloys

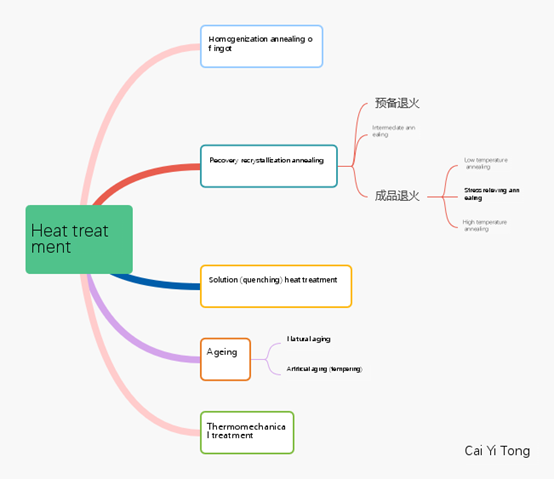

Classification of heat treatment of aluminium alloys

Solution treatment: It refers to the heat treatment process that the alloy is heated to the high temperature single phase region and kept at a constant temperature, so that the excess phase is fully dissolved in the solid solution and then rapidly cooled (water cooling) to obtain the supersaturated solid solution.

Incomplete artificial aging: a relatively low aging temperature or a relatively short holding time is used to obtain excellent comprehensive mechanical properties, that is, to obtain relatively high strength, good plasticity and toughness, but the corrosion resistance may be relatively low.

Full artificial aging: The highest hardness and tensile strength can be obtained by using higher aging temperature and longer holding time, but the elongation is lower.

Stabilization treatment: Heat treatment to keep the shape and dimension change of the workpiece within the specified range under the condition of long-term service.

Natural aging: Place the casting in the open air for more than half a year, and the internal stress of the workpiece will be released naturally, so as to eliminate or reduce the residual stress.

Annealing: a heat treatment process in which a metal or alloy whose structure deviates from equilibrium is heated to a suitable temperature, held for a certain period of time, and then slowly cooled to achieve a structure close to equilibrium.

Aluminum alloy heat treatment code

F Free processing state (applicable to products without special requirements for work hardening and heat treatment conditions during molding, and the mechanical properties of products in this state are not specified)

O Annealed condition (for processed products that have been fully annealed to achieve minimum strength)

H Work hardening status (applicable to products with improved strength through work hardening. After work hardening, the products can be subjected to additional heat treatment to reduce the strength. The H code must be followed by two or three Arabic numerals)

W solution treatment state (an unstable state, only applicable to the alloy naturally aged at room temperature after solution heat treatment, and the state code only indicates that the product is in the natural aging stage)

T Heat treatment condition (applicable to the product which reaches a stable state after heat treatment and work hardening)

T1 Artificial aging T2 Annealing T4 Solution treatment + natural aging T5 Solution treatment + incomplete artificial aging T6 Solution treatment + complete artificial aging T7 Solid solution treatment + stabilization treatment T8 Condition of cold working followed by artificial aging after solution treatment T9 Condition of artificial aging followed by solution treatment followed by cold working

Effect of Heat Treatment on Properties of Aluminum Alloy

The R & D of aluminum alloy materials is mainly focused on improving the comprehensive properties of materials, such as strength, plasticity, toughness, corrosion resistance and fatigue properties, while the properties of alloys are determined by their microstructures, so it is necessary to study and master the macro and micro microstructures of wrought aluminum alloys in various States, as well as the effects of these microstructures on the properties, and to study the microstructure control technology in depth. Heat treatment is the most important means of microstructure control technology.

1 Strengthening method of aluminum alloy

The plastic deformation of aluminum alloy at room temperature and medium stress is mainly caused by dislocation slip, while the plastic deformation at high temperature and low stress is caused by dislocation creep and diffusion flow. In general, regardless of the working temperature, the ability of alloys to resist deformation is mainly determined by the difficulty of dislocation movement. Therefore, increasing the resistance of aluminum alloy to dislocation movement is called strengthening of aluminum alloy.

There are many ways to strengthen and classify aluminum alloys, which are generally divided into two categories: work hardening and alloying strengthening. The strengthening methods of aluminum alloys can be subdivided into seven categories: work hardening, solid solution strengthening, heterogeneous strengthening, dispersion strengthening, precipitation strengthening, grain boundary strengthening and composite strengthening. In the practical application process, several reinforcement methods often work at the same time.

A processing strengthening

Work hardening is a method of obtaining high strength in alloys by plastic deformation (rolling, extrusion, forging, stretching, etc.). The increase of dislocation density during plastic deformation is the essence of work hardening. According to statistics, the dislocation density can be increased from 106 pieces/cm2to more than 1012 pieces/cm2after strong deformation of metal. Because the greater the dislocation density in the alloy, the more opportunities for dislocations to cross each other in the process of sliding when continuing to deform, the greater the resistance between them, so the deformation resistance is greater, and the alloy is strengthened.

The reason for the working strengthening of metal materials is that the dislocations are unevenly distributed during the deformation of metals. At first, the dislocations are tangled in groups in a chaotic manner to form dislocations. With the increase of deformation and deformation temperature, the dislocations change from scattered dislocations to cellular substructures. At this time, the deformed grains are composed of many small units called “cells”. The high density of dislocation tangles is concentrated around the cell to form the envelope wall, and the dislocation density in the cell is very low. These cellular structures impede the movement of dislocations, causing the number of dislocations that cannot move to increase so much that more force is required to move the dislocations over the barrier. The greater the deformation, the smaller the substructure, the greater the ability to resist further deformation, the more obvious the work hardening effect, and the higher the strength. Because of the production of substructure, it is also called substructure strengthening.

The degree of work strengthening varies with the deformation rate, deformation temperature and the nature of the alloy itself. When the same alloy is cold deformed at the same temperature, the greater the deformation rate is, the higher the strength is, but the plasticity decreases with the increase of deformation rate. The distributions of dislocations are different with different deformation conditions. When the deformation temperature is low (such as cold rolling), the dislocation activity is poor, and most of the dislocations are disordered and irregularly distributed after deformation, forming dislocation entanglement. At this time, the strengthening effect of the alloy is good, but the plasticity is also strongly reduced. When the deformation temperature is higher, the dislocation activity is greater, and cross-slip occurs, the dislocation can be locally aggregated, tangled, and form dislocation clusters, resulting in substructure and its strengthening. At that time, the strengthening effect is not as good as that of cold deformation, but the plastic loss is less.

Work hardening or substructure strengthening is a very effective strengthening method at room temperature, which is suitable for industrial pure aluminum, solid solution alloys and multi-phase aluminum alloys that can not be strengthened by heat treatment, but at high temperature, the contribution to strength is usually significantly reduced due to recovery and recrystallization.

Some aluminum alloys can form a better texture and strengthen in a certain direction during cold deformation, which is called texture strengthening.

B solid solution strengthening

When alloying elements dissolve into the base metal (solvent) to form a solid solution, the strength and hardness of the alloy will generally be improved, which is called solid solution strengthening. All soluble alloying elements and even impurities can produce solid solution strengthening. It is particularly valuable that when the alloy is strengthened by solid solution, the strength and hardness can be improved while the plasticity can be maintained at a good level, but this method alone can not achieve a particularly high strength.

When the alloying elements dissolve into the base metal, the dislocation density of the base metal increases and the lattice distortion occurs. The interaction between the stress field generated by the distortion and the elastic stress field around the dislocation makes the atoms of the alloy elements gather near the dislocation line to form the so-called “air mass”. In order to move, the dislocation must overcome the pinning effect of the air mass, move with the air mass, or break away from the air mass. Therefore, greater shear stress is needed. In addition, the atoms of alloying elements can also change the elastic coefficient, diffusion coefficient, cohesive force and arrangement defects of atoms in the solid solution, which can bend the dislocation line and increase the resistance of dislocation movement, including the long-range interaction and short-range interaction between dislocation and solute atoms, thus strengthening the material.

The effect of solid solution strengthening depends on the concentration of solute atoms, the relative size of atoms, the type of solid solution, the electronic factor and the elastic modulus. Generally speaking, the higher the concentration of solute atoms, the greater the strengthening effect. The larger the difference in atomic size, the greater the strengthening effect on the substitutional solid solution. The larger the difference of the number of valence electrons between solute atoms and aluminum atoms is, the larger the solid solution strengthening effect is. The greater the difference of elastic modulus, the better the strengthening effect.

When the alloying of solid solution strengthening is used, the elements with high strengthening effect should be selected as alloying elements. However, it is more important to select those elements with high solid solubility in the base metal as alloying elements, because the strengthening effect of solid solution increases with the increase of the content of solid solution elements. Only those elements with high solid solubility in the base metal can be added in large quantities. For example, copper and magnesium are the main alloying elements of aluminum alloys; Aluminum and zinc are the main alloying elements of magnesium alloys because of their high solid solubility in the base metal.

When carrying out solid solution strengthening, the complex alloying principle of multiple elements and a small amount is often adopted (that is, multiple alloy elements are added at the same time, but the amount of each element added is small), so that the composition of the solid solution is complicated, so that the strengthening effect of the solid solution is higher, and can be maintained at a higher temperature.

C-excess phase strengthening

When excessive alloying elements are added to the base metal, some of them dissolve into the solid solution, and the part exceeding the limit solubility can not dissolve, forming an excess second phase, referred to as the excess phase. The excess phase generally has a strengthening effect on the alloy, and the strengthening effect is related to the properties of the excess phase itself. The higher the strength and hardness of the excess phase, the greater the strengthening effect. However, when the content of hard and brittle excess phase exceeds a certain limit, the alloy becomes brittle and the mechanical properties decrease. In addition, the strengthening effect is also related to the shape, size, quantity and distribution of the excess phase. When the second phase is equiaxed, fine and uniformly distributed, the strengthening effect is the best. The second phase is very large, distributed along the grain boundary or needle-like, especially when it is coarse needle-like, the alloy becomes brittle, the alloy plasticity loss is large, and the strength is not high, so it is not suitable to use a large number of excess strengthening at room temperature, but the use effect at high temperature can be very good. In addition, the strengthening effect is also related to the interface between the matrix phase and the excess phase.

Excess phase strengthening is similar to precipitation strengthening, except that the strengthening phase is very fine and has a large degree of dispersion, which can not be observed under the optical microscope. When the alloy is strengthened by the excess phase, the strengthening phase is coarse and can be clearly seen by the low magnification of the optical microscope. Excess and strengthening are widely used in aluminum alloys, and almost all two-phase alloys used in the annealed state are strengthened by excess phases. Or more precisely, the combined application of solid solution strengthening and excess phase strengthening. Excess phase enhancement is sometimes called heterogeneous enhancement or heterogeneous enhancement.

D Dispersion strengthening

The strengthening of aluminum alloy by incoherent hard particle dispersion is called dispersion strengthening. In order to obtain a good strengthening effect, the dispersoids are required to have low solubility and diffusion rate in the aluminum matrix, high hardness (non-deformability), and small particles (about 0.1 μm). The dispersion may be prepared by powder metallurgy or obtained by high temperature precipitation, resulting in powder metallurgy strengthening and high temperature precipitation strengthening.

The strengthening caused by the dispersed particles includes two aspects: the direct effect of the dispersed particles on the movement of the dislocation, the dispersed particles are non-deformable particles, after the movement of the dislocation is blocked, the more they pass around the particles, the stronger the strengthening effect is, and the denser the dispersion is, the better the strengthening effect is; The dispersed particles affect the recrystallization process of the semi-finished product during the final heat treatment, partially or completely inhibit the recrystallization (there are certain requirements for the size and spacing of the dispersed particles), and improve the strength. Dispersion strengthening is suitable for both normal temperature and high temperature, especially for sintered aluminum alloy produced by powder metallurgy method, the working temperature can reach 350 ℃. The strain of the dispersion-strengthened alloy is not uniform, and the loss of plasticity is greater than that of the solution-strengthened or precipitation-strengthened alloy. More and more attention has been paid to the strengthening of cast metallurgical aluminum alloys by using high temperature treatment to obtain dispersed particles. Transition metals and rare earth elements with very low solubility and diffusion rate, such as Mn, Cr, Zr, Sc, Ti and V, are added to the aluminum alloy. These elements are retained in the α (Al) solid solution by rapid cooling during casting, and then very stable incoherent second phase dispersion particles below 0.5 μm, namely second-type particles, are precipitated by heating at high temperature. The microhardness of the alloy can be more than 5 000 MPa, so that the alloy has the effect of dispersion strengthening.

Once these particles are separated out, they are difficult to continue to dissolve or aggregate, so they have a greater dispersion strengthening effect. Taking Al-Mg-Si alloys as an example, the tensile strength can be increased by 6% ~ 29% by adding different amounts of transition elements, and the yield strength can be increased by 52%. In addition, the dispersion particles prevent recrystallization, that is, increase the recrystallization temperature, so that the effect of cold work hardening is retained to the maximum extent, especially Zr and Sc increase the recrystallization temperature of Al most significantly.

E precipitation strengthening

Precipitation is a process in which a stable second phase is precipitated from a supersaturated solid solution to form a transitional phase in which solute atoms are enriched in the metastable region. Precipitation occurs when the alloy with a change in solid solubility enters the two-phase region from the single-phase region. The supersaturated solid solution is obtained during solution treatment of aluminum alloy, and then heated at a certain temperature to precipitate and form coherent metastable phase particles, which is called aging. Strengthening caused by precipitation or aging is called precipitation strengthening or aging strengthening. The precipitation process of the second phase is also called precipitation, and its strengthening is called precipitation strengthening. The precipitates of aluminum alloy during aging are generally G. P zones, coherent or semi-coherent transition phases, with the size of 0. 001 ~ 0.1 μm, belonging to the third type of precipitates. These soft particles have three strengthening effects, namely, strain strengthening, dispersion strengthening and chemical strengthening. The particles of aging strengthening are uniformly distributed in the matrix, which makes the deformation tend to be uniform, so the plasticity loss caused by aging strengthening is smaller than that caused by work hardening, dispersion strengthening and heterogeneous strengthening. The strength of the alloy can be increased by tens to hundreds of times by precipitation strengthening. Therefore, precipitation strengthening is an effective strengthening method for Ag, Mg, Al, Cu and other non-ferrous metal materials.

The effect of precipitation strengthening depends on the composition of the alloy, the supersaturation of the solid solution after quenching, the characteristics, distribution and dispersivity of the strengthening phase, and the heat treatment system. The alloy with the best strengthening effect is located at the limiting solubility composition, at which the maximum volume fraction of precipitates can be obtained.

F grain boundary strengthening

The grain of aluminum alloy is refined and the grain boundary is increased. Because the resistance of grain boundary movement is greater than that within the grain and the different orientations of adjacent grains make the slip within the grain interfere with each other and blocked, the deformation resistance is increased, that is, the alloy is strengthened. Grain refinement can improve the strength, plasticity and toughness of materials at room temperature, which is one of the most commonly used methods of strengthening and toughening of metal materials. The wrong arrangement of atoms on the grain boundary, magazine abdominal muscles

The dislocation movement from one grain to another is hindered by the disordered arrangement of atoms, the enrichment of impurities, a large number of dislocations, holes and other defects on the grain boundary, and the different orientations of grains on both sides of the grain boundary. The finer the grain size, the larger the grain boundary area per unit volume, the greater the resistance to dislocation movement, and thus the higher the strength of the alloy. The strength of grain boundary itself depends on the existing form and distribution pattern of alloying elements at the grain boundary. The compound is better than the elemental atom adsorption. When the compound is discontinuous and fine dispersed, the grain boundary strengthening effect is the best. Grain boundary strengthening is not suitable at high temperature because grain boundary slip is an important deformation mode at high temperature, which makes the alloy tend to fracture along the grain boundary.

There are three main methods for grain refinement of aluminum alloys.

(1) refine grains of a casting structure;

During casting, the melt is modified by adding appropriate insoluble particles (or elements that can form refractory compound particles with the base metal) into the melt as non-spontaneous crystal nuclei. As the number of crystal nuclei increases substantially, the melt crystallizes into fine grains. For example, the addition of Ti, Ti-B, Zr, Sc, V and so on has a good effect on grain refinement. In addition, the shape of the primary crystal can be changed by adding a small amount of substance to the melt, which has a chemical effect on the primary crystal and thus changes its crystallization properties. For example, Na modification of Al-Si alloy is a good example. Not only the primary grains but also the eutectic and coarse excess phases can be refined or their shapes can be changed by modification. In addition, fine grain ingots can also be obtained by increasing the proportion of first-class high-quality waste, avoiding overheating of the melt, stirring, reducing the casting temperature, increasing the cooling rate, and improving the casting tools.

(2) control that refinement of recrystallized grain of the dispersed phase

Dispersed phases MnAl, MnAl, CrAl, CrAl, TiAl, ScAl, VAl and ZrAl are used to inhibit recrystallization. Many of them are pinned on the grain boundary in the microstructure, which makes it difficult for the grain boundary to migrate. This not only hinders recrystallization, but also increases the interface strength of the grain boundary. The size and distribution of these dispersed phases are the main factors affecting the refinement effect. The finer and more dispersed, the better the refinement effect. The size and distribution of the dispersed phase are mainly affected by high temperature heat treatment and hot working. The main methods to obtain the fine dispersed phase are as follows: low temperature pretreatment and nucleation during homogenization, followed by normal heat treatment; The alloy containing Sc is subjected to low-temperature homogenization treatment; The alloy containing Mn and Cr is homogenized at a higher temperature; The fine dispersed phase can also be obtained by the method of thermomechanical processing and heat treatment, that is, the aluminum alloy after hot working is pretreated at high temperature, and then normal hot working is carried out, such as 7175-T74 alloy forgings. In addition, the dispersoid can also be controlled by the heating process and the solution treatment process of hot working.

(3) adopt a deformation and recrystallization method to refine recrystallized grain;

Fine grain structure can be obtained by recrystallization after strong cold deformation. Tissues containing a large number of substructures can be obtained by medium temperature processing. The microstructure containing a large number of substructures can be obtained by combining appropriate hot extrusion with reasonable recrystallization heat treatment, and good extrusion effect can be obtained. During recrystallization treatment, fine grain structure can be obtained by high temperature and short time or multiple high temperature and short time solution treatment.

G Composite reinforcement

High strength powder, wire and flake materials are used to compound with aluminum matrix by pressing, welding, spraying, leaching and other methods to obtain high strength of the matrix, which is called composite strengthening. According to the shape of composite materials, composite reinforcement can be divided into three types: fiber reinforcement, particle reinforcement and cladding materials. Whiskers and continuous fibers are often used as raw materials for fiber reinforcement. There are two types of particle reinforcement: powder metallurgy and hybrid casting. For the composite strengthening alloy of sintered aluminum and metal particles, most scholars believe that it is a typical alloy of dispersion strengthening. The mechanism of composite strengthening is similar to that of heterogeneous strengthening. This kind of strengthening has the best strengthening effect at high temperature, and can also be significantly strengthened at room temperature, but the loss of plasticity is large. Materials that can be used as the reinforcing fibers include carbon fibers, boron fibers, fibers of refractory compounds (Al3O2, SiC, BN, TiB2, etc.), and filaments of refractory metals (W, Mo, Be, etc.). The strength of these fibers or filaments is generally 2500 to 3500 MPa. In addition, metal single crystal whiskers or ceramic single crystal whiskers such as Al3O2and B4C can be used as reinforcing fibers, and their strength is higher. However, the production of whiskers is very difficult and costly.

Aluminum alloy is a typical matrix material. Metallic composites based on the boron fiber reinforced and heat treatable alloys (such as Al-Cu-Mg, Al-Mg-Si) or dispersion hardened Al-Al3O2systems have a strength to weight ratio of 2 to 3.5 times that of standard aluminum alloys and have been used in the aerospace industry.

The strengthening mechanism of metal matrix composites is different from the above solid solution strengthening and dispersion strengthening mechanisms. This strengthening is not mainly based on the hindrance of dislocation movement, but on the good wettability and close bonding between the fiber and the matrix, so that the good bonding strength between the fiber and the matrix can be obtained. In this way, because the matrix material has good plasticity and toughness, and the reinforcing fibers have high strength and can bear large axial load, the whole material has high tensile strength and excellent toughness. In addition, this kind of material can also obtain high specific strength, high heat resistance and corrosion resistance, which is a new direction of material development at present.

2 Application of Various Strengthening Methods in Aluminum Alloy Production

Strengthening of non-heat-treatable aluminum alloy

Pure aluminum, Al-Mg, Al-Mg-Sc and Al-Mn alloys are non-heat-treatable strengthening aluminum alloys, which mainly depend on work hardening and grain boundary strengthening to obtain high strength, and the auxiliary strengthening mechanisms include solid solution strengthening, excess phase strengthening, dispersion phase strengthening and so on. Work hardening can be achieved to varying degrees by hot deformation, cold deformation, and partial annealing after cold deformation. The higher the deformation temperature is, the larger the subgrain size is, and the worse the strengthening effect is, but the plasticity is quite high. The greater the cold deformation rate, the higher the strength of the product, but the lower the plasticity. The work hardening effect of cold deformation is the greatest. The fully cold deformed products are annealed at different temperatures, and the recovery and recrystallization stages are controlled, so that different degrees of work hardening, namely different strengthening effects, can be retained.

Strengthening of heat-treatable aluminum alloy

Industrially produced heat-treatable strengthening aluminum alloys include Al-Cu-Mg, Al-Cu-Mn, Al-Mg-Si, Al-Zn-Mg and Al-Zn-Mg-Cu alloys, as well as developing Al-Cu-Li and Al-Mg-Li alloys. Quenching and aging are commonly used in these alloys, and precipitation strengthening is mainly used to obtain high strength. The auxiliary strengthening mechanisms include solid solution strengthening, excess phase strengthening, dispersion phase strengthening, grain boundary strengthening and so on. During natural aging, the main strengthening phase is in the G. P zone, and during artificial aging, the main strengthening phase is in the G. P zone plus the transition phase. The stable phase appears after overaging, and the strength decreases after the appearance of the stable phase.

Deformation aging and extrusion effect strengthening

In Al-Cu and Al-Mg-Si alloys, the deformation aging method is more used to obtain high strength. This method includes T3, T8 and T9 States, which are all due to the interaction of aging strengthening and cold work hardening and the superposition of strengthening to a certain extent. A large number of slip lines are produced due to cold deformation of 2124-T8 thick plate, and aging precipitates are distributed in rows on the slip lines. The combined effect of the two makes the plastic deformation more difficult, that is, the strength is further improved.

Extrusion effect refers to the phenomenon that the strength of heat treatable aluminum alloy extrusion products after quenching and aging is higher than that of the same alloy produced by other methods in the same heat treatment state. The microstructure observation shows that all or part of the cold work hardening effect is retained, and a large number of substructures are retained in the matrix, so the strengthening is the superposition of aging strengthening and substructure strengthening.

Strengthening of Al-Si alloy

The Al-Si series wrought aluminum alloy is especially suitable for the production of die forgings such as pistons. The silicon content in the alloy is ω (Si) = 12% ~ 13%, and it also contains a certain amount of Cu, Mg, Ni, etc. There is a lot of eutectic silicon formed during crystallization in the microstructure, which is uniformly distributed on the soft α (Al) matrix, and the size is mostly about 5 μm, which is hard and brittle. This eutectic silicon is a typical example of heterogeneous strengthening in aluminum alloys. Because the heterogeneous strengthening has the characteristics of high temperature resistance, wear resistance, medium strength and the like, the heterogeneous strengthening is particularly suitable for manufacturing pistons.